Page 1 of 2

Lee Precision = Perfection! (well, almost)

Posted: Wed Feb 15, 2012 5:08 pm

by v-rog

Re: Lee Precision = Perfection! (well, almost)

Posted: Wed Feb 15, 2012 6:23 pm

by Don2

AndyC wrote:Ok - you're officially having way too much fun with that....

That is EXACTLY what I was going to say..!!!

I made up a bunch of that same type bullet but 230 gn-RN and ended up playing with them too...Had them in a big plastic container going through them like silver coins

You gotta have a little fun some times..!

Don2

Re: Lee Precision = Perfection! (well, almost)

Posted: Thu Feb 16, 2012 7:57 am

by Jumping Frog

Load 50 or so and make sure they will feed in your gun before you load them all. Taking a bunch of rounds apart with an impact hammer is tedious.

That particular Lee mold will not feed in a lot of guns. If they work in your gun, that's great. They wouldn't feed in mine so I gave the mold to a friend because they fed just fine in his .45. Some .45's will even feed empty cases, others are more picky.

Forget about whatever people have told you about loading a 200 gr LSWC to an overall length of 1.250". That COL works great for an H&G 68 style of bullet, but the Lee TL452-200-SWC has a

completely different nose profile.

If you load to that length, you'll have almost 0.100" of bullet base sticking above the case and it will never chamber in a gun -- the shoulder will jam (hard) into the rifling. They are a real ****** to unjam in the gun too (I know the hard way). No, the correct way to load the LSWC profile is to have about 0.030" of the shoulder showing above the case rim - about the width of a fingernail.

That means this bullet design requires a cartridge length of about 1.182", calculated as 0.898" case length + 0.030" shoulder above case rim + 0.254" bullet nose. Note also that the Lee bullet base is roughly 0.028" longer than the Lyman base, which means a Lee-loaded round has about 9.5% less case capacity than a Lyman-loaded round. Thus, make sure you stay on the lower end of the loading chart -- no max loads.

Here is a picture I took of bullets I cast from a Lyman 452630 mold versus the Lee TL-452-200-SWC. Look at the nose profile. It is short and squat compared to the Lyman.

This also shows the nose profile when both are seated to give a similar shoulder.

Good luck with your new endeavor.

Re: Lee Precision = Perfection! (well, almost)

Posted: Thu Feb 16, 2012 9:03 am

by v-rog

Are you also "JPFROG" on CCIDPA forum?

Yes, I've been shooting this particular round for about 7 months. Probably 2K+ rounds. I use a 1.180 OAL with 6.7-6.8 gr of Power Pistol through my S&W M&P mid-size 45.. I use it exclusively in IDPA.

Jumping Frog wrote:Load 50 or so and make sure they will feed in your gun before you load them all. Taking a bunch of rounds apart with an impact hammer is tedious.

That particular Lee mold will not feed in a lot of guns. If they work in your gun, that's great. They wouldn't feed in mine so I gave the mold to a friend because they fed just fine in his .45. Some .45's will even feed empty cases, others are more picky.

Forget about whatever people have told you about loading a 200 gr LSWC to an overall length of 1.250". That COL works great for an H&G 68 style of bullet, but the Lee TL452-200-SWC has a

completely different nose profile.

If you load to that length, you'll have almost 0.100" of bullet base sticking above the case and it will never chamber in a gun -- the shoulder will jam (hard) into the rifling. They are a real ****** to unjam in the gun too (I know the hard way). No, the correct way to load the LSWC profile is to have about 0.030" of the shoulder showing above the case rim - about the width of a fingernail.

That means this bullet design requires a cartridge length of about 1.182", calculated as 0.898" case length + 0.030" shoulder above case rim + 0.254" bullet nose. Note also that the Lee bullet base is roughly 0.028" longer than the Lyman base, which means a Lee-loaded round has about 9.5% less case capacity than a Lyman-loaded round. Thus, make sure you stay on the lower end of the loading chart -- no max loads.

Here is a picture I took of bullets I cast from a Lyman 452630 mold versus the Lee TL-452-200-SWC. Look at the nose profile. It is short and squat compared to the Lyman.

This also shows the nose profile when both are seated to give a similar shoulder.

Good luck with your new endeavor.

Re: Lee Precision = Perfection! (well, almost)

Posted: Thu Feb 16, 2012 10:02 pm

by slinco

And here I thought I had too much time on my hands....

Re: Lee Precision = Perfection! (well, almost)

Posted: Fri Feb 17, 2012 12:51 am

by Don2

Jumping Frog wrote:Load 50 or so and make sure they will feed in your gun before you load them all. Taking a bunch of rounds apart with an impact hammer is tedious.

That particular Lee mold will not feed in a lot of guns. If they work in your gun, that's great. They wouldn't feed in mine so I gave the mold to a friend because they fed just fine in his .45. Some .45's will even feed empty cases, others are more picky.

Forget about whatever people have told you about loading a 200 gr LSWC to an overall length of 1.250". That COL works great for an H&G 68 style of bullet, but the Lee TL452-200-SWC has a

completely different nose profile.

If you load to that length, you'll have almost 0.100" of bullet base sticking above the case and it will never chamber in a gun -- the shoulder will jam (hard) into the rifling. They are a real ****** to unjam in the gun too (I know the hard way). No, the correct way to load the LSWC profile is to have about 0.030" of the shoulder showing above the case rim - about the width of a fingernail.

That means this bullet design requires a cartridge length of about 1.182", calculated as 0.898" case length + 0.030" shoulder above case rim + 0.254" bullet nose. Note also that the Lee bullet base is roughly 0.028" longer than the Lyman base, which means a Lee-loaded round has about 9.5% less case capacity than a Lyman-loaded round. Thus, make sure you stay on the lower end of the loading chart -- no max loads.

Here is a picture I took of bullets I cast from a Lyman 452630 mold versus the Lee TL-452-200-SWC. Look at the nose profile. It is short and squat compared to the Lyman.

This also shows the nose profile when both are seated to give a similar shoulder.

Good luck with your new endeavor.

Good info Sir.

Don2

Re: Lee Precision = Perfection! (well, almost)

Posted: Fri Feb 17, 2012 7:27 am

by Jumping Frog

v-rog wrote:Are you also "JPFROG" on CCIDPA forum?

Nope, but I am Jumping Frog on about 8 or 9 different gun forums over the years.

v-rog wrote:Yes, I've been shooting this particular round for about 7 months. Probably 2K+ rounds. I use a 1.180 OAL with 6.7-6.8 gr of Power Pistol through my S&W M&P mid-size 45.. I use it exclusively in IDPA.

I am really glad to hear that. I use my 200 gr LSWC bullets to shoot CDP in IDPA.

Switching gears, those Lee 6 bangers can really pump out the bullets, can't they! I wasn't able to get their mold in .45 to work for me, but I also cast 9mm and .40 S&W with the Lee mold and am a big fan.

Re: Lee Precision = Perfection! (well, almost)

Posted: Sun Feb 19, 2012 7:29 pm

by Mr.ViperBoa

That is really awesome. I just shot my first 10 reloads ever yesterday and it was great. Except for the fact that the range was packed and I couldnt find all my brass. But I am very interested in gettting into casting. Great photo.

Re: Lee Precision = Perfection! (well, almost)

Posted: Sun Feb 19, 2012 9:14 pm

by Jumping Frog

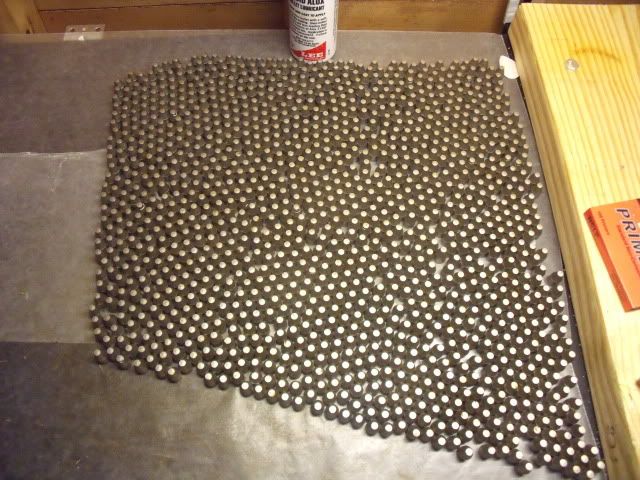

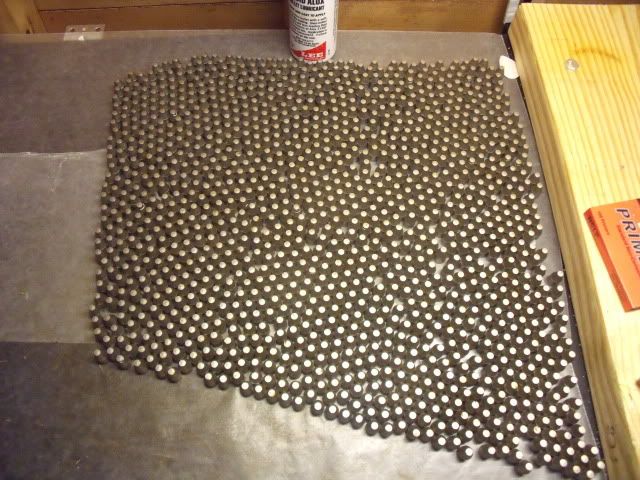

You are having so much fun lining them up, I thought I would contribute to the party.

Water quenched Lee 6 banger TL356-124TC:

Re: Lee Precision = Perfection! (well, almost)

Posted: Sun Feb 19, 2012 11:52 pm

by texasmusic

To you cast bullet guys:

How economical would it be to cast my own without a source of scrap lead? Is it something to look into for a low-volume reloader or keep buying the berry's bullets when I can?

Re: Lee Precision = Perfection! (well, almost)

Posted: Mon Feb 20, 2012 7:30 pm

by Jumping Frog

texasmusic wrote:To you cast bullet guys:

How economical would it be to cast my own without a source of scrap lead? Is it something to look into for a low-volume reloader or keep buying the berry's bullets when I can?

Well, free lead helps a lot, but the math involved isn't rocket science and you could calculate it pretty easily.

For example, my most recent .45 ACP reloads using my own cast bullets cost me about $2.83 per hundred. That is because I was using primers at $20 per thousand ($2/hundred), and

Clays powder at $0.83 per hundred.

If I purchased Missouri Bullet Co's 200 gr LSWC bullets, they are about $80 per thousand, or $8 per hundred. That increases my reload cost to $10.83 per hundred.

Now, let's compare costs if I cast using purchased lead. A hundred bullets at 200 grains ea is 20,000 grains. There are 7,000 grains in a lb., so 20,0000/7,0000 = 2.86 lbs of lead. If you are paying $1/lb, those bullets cost you $2.86 per hundred, which is still a substantial savings over purchasing $8.00 per hundred from MBC.

You can compare that for any caliber and bullet weight. For example, 115 gr 9mm? A hundred rounds is 11500 grains or 1.64 lb = $1.64. Same bullets from MBC cost $5.90 per hundred.

Another example, 240 gr .44 Magnum. is 24000 grains per hundred = 3.43 lb = $3.43. Same bullet from MBC is $9.30 per hundred. Same lead 240 gr bullet from Hornady is $18.80 per hundred.

Re: Lee Precision = Perfection! (well, almost)

Posted: Wed Feb 22, 2012 12:40 am

by texasmusic

Andy,

Low volume for me is maybe 400 a month. I can't get to the range often enough to get my and keep loading. I'm sure once I get a thousand loads under my belt I'll start doing much more, my bras supply is also growing I always bring back more than I take.

Jfrog,

I'm going to bookmark this for the future... I don't think I really have the space to start a casting operation right now. And I'll have less stuff to lug around when I move within a few months. (I'm on the move too much right now to be collecting TOO much stuff

)

Thanks!