Is anyone using a Redding precision seating die for a pistol caliber in a Dillon XL650? I'm considering one to make it faster and easier to change bullet types/lengths. If you are using one, how do you like it? Is the mouth of the die chamfered to make it work better with a progressive press?

Thanks,

Chas.

Question: Redding precision seating die in Dillon XL650

Moderators: carlson1, Charles L. Cotton

- Charles L. Cotton

- Site Admin

- Posts: 17788

- Joined: Wed Dec 22, 2004 9:31 pm

- Location: Friendswood, TX

- Contact:

Re: Question: Redding precision seating die in Dillon SL650

No but... I use a Redding Competition seating die for .45 ACP. It is chamfered and and very AP friendly. I really only load two projectiles; semi-wadcutter and jacketed round nose. I have the depth set such that for SWC I turn the micrometer all the way down to zero and for the round nose and raise it 2 full turns and continue to 28. When I make the change I always test my result and I am always pleased to see that it reliably repeats. The spring loaded seating cup straightens the projectile before you get to seating depth. What's not to like? (I also use Redding dual ring sizing die and Redding micrometer crimp die. I guess I am a Redding fanboy.)Charles L. Cotton wrote:Is anyone using a Redding precision seating die for a pistol caliber in a Dillon XL650? I'm considering one to make it faster and easier to change bullet types/lengths. If you are using one, how do you like it? Is the mouth of the die chamfered to make it work better with a progressive press?

Thanks,

Chas.

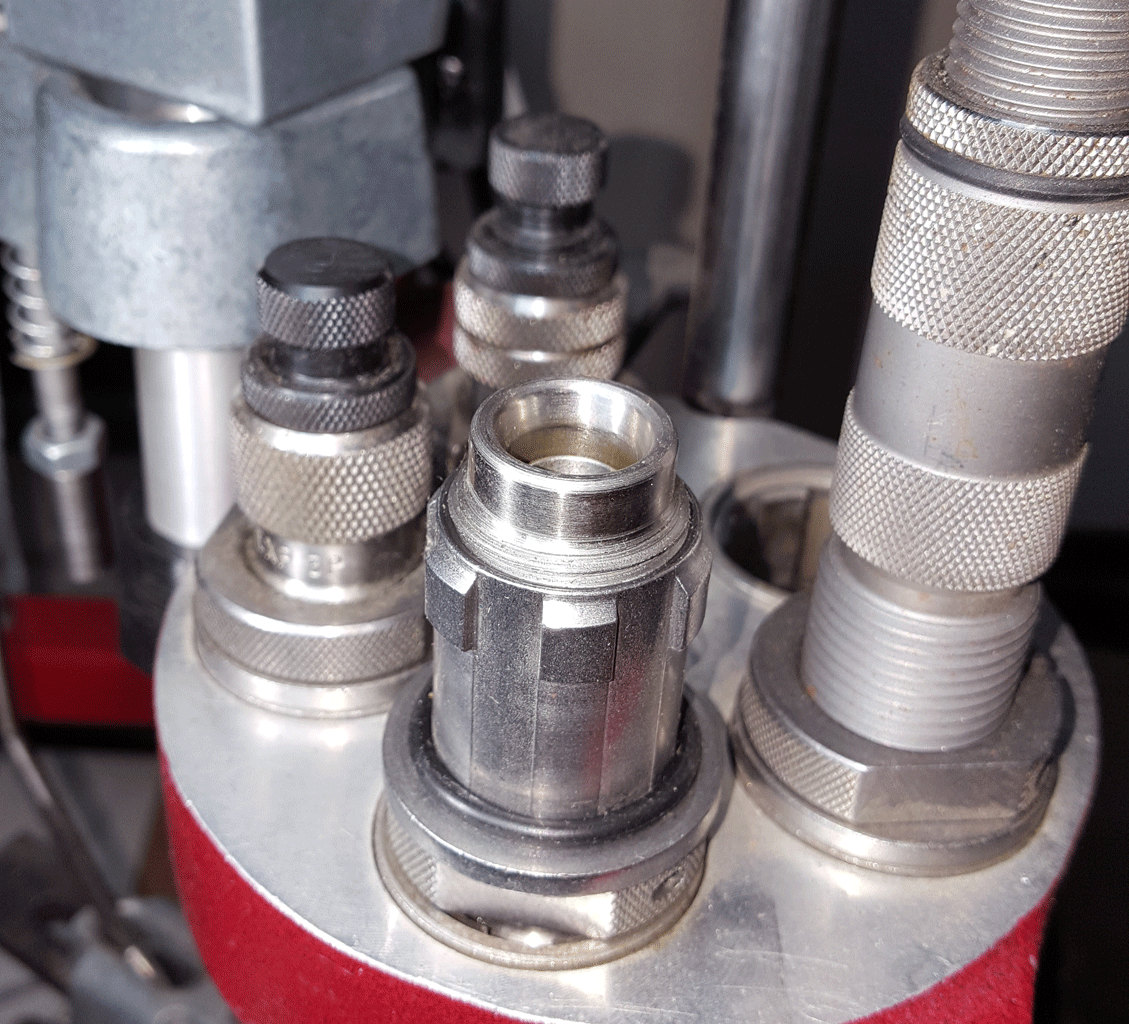

This is a picture of the business end and the chamfer.